Machining Center

Main Features:

- 5-Axis Horizontal Machining Center suitable for machining small →medium sized shells, complex box parts with spatial surfaces

- 5-Axis Vertical Machining Center suitable for high-precision and complex shaped parts (such as impellers, integral impellers, molds, automotive components, etc.), excellent tool tip point following function (RTCP), turning options available.

- Complex Milling & Turning Machining Center,suitable for small and medium-sized batch, multi variety, high-precision part machining. With excellent tool tip point following function (RTCP).

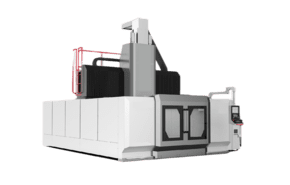

- Fixed Beam Gantry Machining Center, work for industries:rail transit, aerospace, and general equipment. Processing high-temperature aluminum alloys, titanium alloys, stainless steel, etc, with exellent rigidity and high torque

- Aircraft Honeycomb Machining Center is a bridge type gantry machining center with 6-axis 5-linkage. Applied in industries:aviation, aerospace, and machinery, processing honeycomb core materials (aramid honeycomb, absorbing honeycomb, paper honeycomb), carbon fiber board, and carbon tube honeycomb structural components with various complex surfaces, sinks, edges, and grooves.

Small → Medium Parts with Spatial Surfaces Manufacturing

5-Axis Horizontal Machining Center

Suitable for machining small and medium-sized shells, complex box parts with spatial surfaces

Impellers, Integral impellers, Molds, Automotive Parts Manufacturing

5-Axis Vertical Machining Center

Suitable for machining small and medium-sized shells, complex box parts with spatial surfaces

Small → Medium Parts with multi-batch, multi variety parts Processing

Milling & Turning Machining Center

Complex Milling & Turning Machining Center,suitable for small and medium-sized batch, multi variety, high-precision part machining. With excellent tool tip point following function (RTCP).

Aluminum Alloys, Titanium Alloys, Stainless Steel Material Processing

Gantry Machining Center

Work for industries:rail transit, aerospace, and general equipment. Processing high-temperature aluminum alloys, titanium alloys, stainless steel, etc, with exellent rigidity and high torque

5-Axis Horizontal Machining Center

Suitable for small → medium Parts with spatial Surfaces Manufacturing

| Model | Features | Start Price |

|---|---|---|

| HMC-630-F5 (5-axis) | Processing Scope X/Y/Z axis Stroke (mm): 1000/1150/1000 Maximum workpiece Dia.(mm): 800 Spindle Spindle Rated Power (kW): 35kW Spindle Max. Speed (rpm):15000rpm Spindle Rated Torque (Nm): 210 Feed Speed X/Y/Z axis Max. Cutting Speed (m/min): 15 X/Y/Z axis Max. Rapid Moving Speed (m/min): 40 Accuracy X/Y/Z axis Positioning Accuracy (mm): 0.008 XYZ axis Repeatable Positioning Accuracy (mm): 0.005 Knife System Nos. of Knives: 40/60 | USD84,000 |

| HMC-800-F5 (5-axis) | Processing Scope X/Y/Z axis Stroke (mm): 1150/1250/1200 Maximum workpiece Dia.(mm): 1000 Spindle Spindle Rated Power (kW): 35kW Spindle Max. Speed (rpm):15000rpm Spindle Rated Torque (Nm): 210 Feed Speed X/Y/Z axis Max. Cutting Speed (m/min): 15 X/Y/Z axis Max. Rapid Moving Speed (m/min): 40 Accuracy X/Y/Z axis Positioning Accuracy (mm): 0.008 XYZ axis Repeatable Positioning Accuracy (mm): 0.005 Knife System Nos. of Knives: 40/60 | USD70,000 |

| HMC-100/5S (SAJO10000) (5-axis) | Processing Scope X/Y/Z axis Stroke (mm): 1500/1250/1500 Maximum Table Dia.(mm): 1000 Spindle Spindle Rated Power (kW): 52/48 Spindle Max. Speed (rpm):7000/12000 Spindle Rated Torque (Nm): 500/300 Feed Speed X/Y/Z axis Max. Rapid Moving Speed (mm/min): 2000 Accuracy X/Y/Z axis Positioning Accuracy (mm): 0.006 XYZ axis Repeatable Positioning Accuracy (mm): 0.004 Knife System Nos. of Knives: 60/80/100 | |

| HMC-120/5S (SAJO10000) (5-axis) | Processing Scope X/Y/Z axis Stroke (mm): 2000/1750/1800 Maximum Table Dia.(mm): 1250 Spindle Spindle Rated Power (kW): 52 Spindle Max. Speed (rpm):7000 Spindle Rated Torque (Nm): 700 Feed Speed X/Y/Z axis Max. Rapid Moving Speed (m/min): 20 Accuracy X/Y/Z axis Positioning Accuracy (mm): 0.007 XYZ axis Repeatable Positioning Accuracy (mm): 0.005 Knife System Nos. of Knives: 60T | |

| HMC-160/5S (SAJO10000) (5-axis) | Processing Scope X/Y/Z axis Stroke (mm): 2000/1750/1700 Maximum Table Dia.(mm): 1600 Workpiece Rotation Dia.(mm):2300 Spindle Spindle Rated Power (S1~100%) (kW): 52 Spindle Rated Power (S6~40%) (kW): 73 Spindle Max. Speed (rpm):7000 Spindle Rated Torque (S1~100%) (Nm): 500 Spindle Rated Torque (S6~40%) (Nm): 700 Feed Speed X/Y/Z axis Max. Rapid Moving Speed (m/min): 20 X/Y/Z axis Min. resolution (mm): 0.001 Accuracy X/Y/Z axis Positioning Accuracy (mm): 0.007 XYZ axis Repeatable Positioning Accuracy (mm): 0.005 Knife System Nos. of Knives: | |

| HMC-P-100/5S (SAJO10000) (5-axis) | Processing Scope X/Y/Z axis Stroke (mm): 1500/1250/1400 Maximum Table Dia.(mm): 1000 Spindle Spindle Rated Power (kW): 52/48 Spindle Max. Speed (rpm):7000/12000 Spindle Rated Torque (Nm): 500/300 Feed Speed X/Y/Z axis Max. Rapid Moving Speed (mm/min): 2000 Accuracy X/Y/Z axis Positioning Accuracy (mm): 0.006 XYZ axis Repeatable Positioning Accuracy (mm): 0.004 Knife System Nos. of Knives: 60/80/100 | |

| HMC-P-80 (4-axis) | Processing Scope X/Y/Z axis Stroke (mm): 1300/1000/1150 Maximum Table Dia.(mm): 1000 Spindle Spindle Rated Power (kW): 26kW Spindle Max. Speed (rpm):8000rpm Spindle Rated Torque (Nm): 512 Feed Speed X/Y/Z axis Max. Rapid Moving Speed (m/min): 40 Accuracy X/Y/Z axis Positioning Accuracy (mm): 0.006 XYZ axis Repeatable Positioning Accuracy (mm): 0.004 Knife System Nos. of Knives: 40/60/Customized | |

| HMC-P-100 (4-axis) | Processing Scope X/Y/Z axis Stroke (mm): 1500/1250/1400 Maximum Table Dia.(mm): 1000 Spindle Spindle Rated Power (kW): 41kW Spindle Max. Speed (rpm):6000rpm Spindle Rated Torque (Nm): 1250 Feed Speed X/Y/Z axis Max. Rapid Moving Speed (m/min): 20 Accuracy X/Y/Z axis Positioning Accuracy (mm): 0.006 XYZ axis Repeatable Positioning Accuracy (mm): 0.004 Knife System Nos. of Knives: 40/60/Customized | |

| HMC-P-120 (4-axis) | Processing Scope X/Y/Z axis Stroke (mm): 2000/1500/1800 Maximum Table Dia.(mm): 1250 Spindle Spindle Rated Power (kW): 41kW Spindle Max. Speed (rpm):6000rpm Spindle Rated Torque (Nm): 1250 Feed Speed X/Y/Z axis Max. Rapid Moving Speed (m/min): 20 Accuracy X/Y/Z axis Positioning Accuracy (mm): 0.006 XYZ axis Repeatable Positioning Accuracy (mm): 0.004 Knife System Nos. of Knives: 40/60/Customized | |

| HMC-P-160/T (4-axis) | Processing Scope X/Y/Z axis Stroke (mm): 2000/1750/1700 Maximum Table Dia.(mm): 1400 Spindle Spindle Rated Power (kW): 41kW Spindle Max. Speed (rpm):4000rpm Spindle Rated Torque (Nm): 1300 Feed Speed X/Y/Z axis Max. Rapid Moving Speed (m/min): 20 Accuracy X/Y/Z axis Positioning Accuracy (mm): 0.007 XYZ axis Repeatable Positioning Accuracy (mm): 0.005 Knife System Nos. of Knives: 40/60/Customized |

5-Axis Vertical Machining Center

Impellers, Integral impellers, Molds, Automotive Parts Manufacturing

| Model | Features | Start Price |

|---|---|---|

| VMC-40-U | Processing Scope X/Y/Z axis Stroke (mm): 500/560/450 Table Rotary Speed (C-axis) : 200rpm (milling); 1000 rpm (turning,optional) Spindle Spindle Rated Power (kW): 25/54 Spindle Max. Speed (rpm):14000/12000 Spindle Rated Torque (Nm): 83/200 Feed Speed X/Y/Z axis Max. Rapid Moving Speed (m/min): 60 X/Y/Z axis Max. Feed Speed (m/min): 60 Accuracy X/Y/Z axis Positioning Accuracy (mm): 0.003 XYZ axis Repeatable Positioning Accuracy (mm): 0.002 Knife System Nos. of Knives: T24 | USD84,000 |

| VMC-500-F5 | Processing Scope X/Y/Z axis Stroke (mm): 550/560/450 Table Rotary Speed (C-axis) : 200 rpm Cradle A-axis Max. Speed: 300 rpm Max. Driving Torque: 1750 x 2 (double driving) Nm Clamping Torque: 2300 x 2 (double driving) Nm Spindle Spindle Rated Power (kW): 25 Spindle Max. Speed (rpm):20000 (18000/24000,alternatively) Spindle Rated Torque (Nm): 82 Feed Speed X/Y/Z axis Max. Rapid Moving Speed (m/min): 60 Accuracy X/Y/Z axis Positioning Accuracy (mm): 0.006/0.006/0.005 XYZ axis Repeatable Positioning Accuracy (mm): 0.004/0.004/0.003 Knife System Nos. of Knives: 30 | |

| VMC-630-F5 | Processing Scope X/Y/Z axis Stroke (mm): 650/650/510 Max. Mounting Dia. (mm) : 800 Spindle Spindle Rated/Max. Speed (rpm): 4000/18000 rpm Spindle Rated Torque (S1) 100% : 30 Nm Spindle Rated Torque (S1) : 72 Nm Feed Speed X/Y/Z axis Max. Feed Speed (m/min): 60/60/60 m/min A/C axis Max. Feed Speed (m/min): 30/100 rpm Accuracy Control System Resolution: 0.1μm X/Y/Z-axis Positioning Accuracy (mm): 0.006/0.005/0.005 X/Y/Z-axis Repeatable Positioning Accuracy (mm): 0.004/0.004/0.003 Knife System Nos. of Knives: 36 |

Milling & Turning Machining Center

Suitable for Small → Medium Parts with multi-batch, multi variety parts Processing

| Model | Features | Start Price |

|---|---|---|

| VMT-100A | Processing Scope X/Y/Z axis Stroke (mm): 1200/1000/1000 mm Table Max.Speed (C-axis): 20/300 (milling/turning) rpm C-axis Driving Torque: 3200Nm C-axis Mounting Torque:4500 Nm Spindle Spindle Rated Power: 54 Kw Spindle Max. Speed: 12000 rpm Spindle Rated Torque: 200 Nm Feed Speed X/Y/Z axis Max. Rapid Moving Speed : 30 m/min Accuracy ISO230-2 X/Y/Z-axis Positioning Accuracy : 0.008mm X/Y/Z-axis Repeatable Positioning Accuracy : 0.005mm Knife System Nos. of Knives: 24 ( 40, optional) | USD84,000 |

| VMT-125 | Processing Scope X/Y/Z axis Stroke (mm): 1200/1000/1000 mm Table Max.Speed (C-axis): 20/300 (milling/turning) rpm C-axis Driving Torque: 3200Nm C-axis Mounting Torque:4500 Nm Spindle Spindle Max. Speed: 10000 rpm *Spindle Rated Power (Contineous S1): 50 Kw Spindle Max. Power (S6): 70kW *Spindle Rated Torque (Contineous S1): 400Nm Max. torque (S6): 560 Nm Feed Speed X/Y/Z axis Max. Rapid Moving Speed : 30m/min or 60m/min Maximum cutting feed rate Accuracy ISO X/Y/Z-axis Positioning Accuracy : 0.006mm X/Y/Z-axis Repeatable Positioning Accuracy : 0.004mm Knife System Nos. of Knives: 40 | USD70,000 |

| VMT-200-F5 | Processing Scope X/Y/Z axis Stroke (mm): 3050/2500/1600 mm X/Y/Z axis Max. Rapid Moving Speed : 30m/min or 60m/min Max. turning Dia.: 2500mm Table Max.Speed (turning): 5~150 rpm Workbench Torque: 56,000Nm Spindle Spindle Max. Speed: 10000 rpm Spindle Max. Power (Contineous): 54 Kw Spindle Max. Torque(Contineous): 200/315 Nm X/Y/Z-axis Positioning Accuracy: 0.015mm X/Y/Z-axis Repeatable Positioning Accuracy : 0.007mm Knife System Nos. of Knives: 40T |

Gantry Machining Center

Suitable for Aluminum Alloys, Titanium Alloys, Stainless Steel Material Processing

| Model | Features | Start Price |

|---|---|---|

| GUM-6020 Honeycomb Core Material Processing (6-axis 5-linkages) | Processing Scope Max. workpiece L/W/H: 6000 x 2000 X 1000 mm X/Y/Z axis Stroke (mm): 6000/2600 /1250 mm X/Y/Z axis Max. Rapid Moving Speed : 30/3 /10 m/min Spindle Max. Speed: 10000 rpm Spindle Rated Power: 20 Kw Spindle Rated Torque: 23Nm Max. speed: 20000 rpm | USD84,000 |